Most people know that the FAA is responsible for certifying pilots (or airmen, as the FAA calls them). But did you know that the FAA also certifies aircraft? And not just when it comes to N-numbers and registrations, either. When a manufacturer wants to build a new airplane type, the design must go through a lengthy certification process.

TLDR – If an airplane design becomes certified, the manufacturer is granted a type certificate (TC). The TC lays out exactly how the plane shall be built, its limitations, and how the company will ensure that each plane they make conforms to the original design. The type certificate grants the holder the power to produce that type of aircraft so long as they make it to those approved standards. A type certificate is a sort of “production certificate.”

What is a Type Certificate?

Certifying a new aircraft is no joke – it’s a lengthy and expensive process that can take years.

A type certificate is issued after a long relationship has been established between a manufacturer and the FAA. The FAA is looking at the aircraft’s design for safety and at the manufacturing process used. Are there sufficient quality control standards in place? Will all of the parts and equipment be built to the same standards?

The FAA website has an extensive library of documents relating to aircraft certification. They list five phases to the certification process, which are laid out in FAA Order 8110.4. They include the conceptual design, requirements definition, compliance planning, implementation, and post-certification.

To get a type certificate, the manufacturer must follow the standards laid out in the Federal Aviation Regulations, Part 21. The organization must create a project specific certification plan (PSCP) that lays out exactly how the company intends to meet the requirements of the regulations.

Under FAR Part 21, the FAA requires design specifications, inspection and testing, and flight tests.

Type Certificate Data Sheet (TCDS)

A key part of the finished type certificate is the type certificate data sheet (TCDS). The TCDS lays out the design in terms of specific numbers.

For example, the TCDS for the Cessna 152 trainer contains all of the pertinent information related to the type. The same TCDS is used for all Cessna 150/152 models, with amendments made to add new engine and propeller combinations. Specific limitations include that a current weight and balance report must be on board, and there must be specific placards in view of the pilot.

For each amended aircraft model, the TCDS lists the installed engine and propeller (and their limitations), airspeed limitations, the available center of gravity range, and the maximum weight of the aircraft. The control surfaces, their designed movements, and the fuel and oil tanks’ capacities are also included.

All of the details found in the TCDS are also found in the approved pilot’s operating handbook or airplane flight manual, where the pilot most often finds them.

All approved TCDS’s can be found online at the FAA’s Regulatory and Guidance Library (RGL) website.

Difference Between a Type Certificate and an Airworthiness Certificate

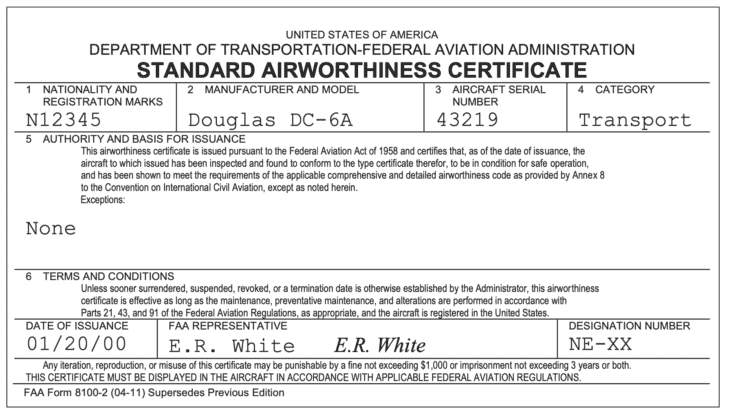

Each aircraft must possess an airworthiness certificate, which must be on board at all times and clearly displayed. It comes with the aircraft and stays with the aircraft. It remains valid as long as that plane is maintained to the regulations’ airworthiness standards and remains unmodified.

The type certificate, on the other hand, is issued to the manufacturer. The airworthiness certificate found in your airplane indicates that it was built by someone who holds a type certificate and is therefore allowed to produce aircraft.

The type certificate’s purpose is that it allows the manufacturer to get airworthiness certificates for all of the aircraft they produce of that type without further testing. If a manufacturer didn’t have a TC, they’d have to get every single airplane approved by the FAA.

What is an FAA Supplemental Type Certificate?

We’ve all known people who like to tinker with their cars. They put fancy spoilers on the trunk, lower the wheels, or change the size tires they use.

But airplanes are not like cars. Making a physical change to the airframe or engine could cause unintended consequences, like unforgiving stall characteristics or controllability issues.

Nonetheless, companies do make modification kits for aircraft. But to sell them, they need to go through a testing and certification process, not unlike the one the manufacturer had to. When the modification is shown not to affect the aircraft’s safety, and when the changes in performance characteristics are well known, the FAA issues them a supplemental type certificate, or STC.

STC holders can then sell their modifications to owners of that type of airplane. For example, say you wanted to turn your Cessna 172 into a STOL (short takeoff and landing) airplane. You might contact Skyway Group to have them install their STC’d R/STOL system on your 172.

This is a pretty complex STC that changes a lot of the performance characteristics of the plane. The STC will require new performance tables for the pilot’s operating handbook, new placards in the cockpit, and new markings on the airspeed indicator. Once all of the changes to the plane have been made, the logbooks are updated, and a copy of the STC is added to the supplements section.

Do Experimental Aircraft Have Type Certificates?

The length of time it takes to prototype and test a new aircraft design when combined with the FAA certification process, add high costs for the manufacturers. This results in more expensive airplanes for consumers.

Of course, this testing and approval process is necessary for safety. If anyone were allowed to make airplanes, it would be a free-for-all in terms of safety for the flying public. If a plane is used for commercial service or to carry the general public, they need to have gone through this process.

But the FAA acknowledges that this process is arduous, and they provide an easy way around it to save private aircraft owners from some of the expenses. A manufacturer can produce an aircraft under the “home-built” rules if the owner does at least 51 percent of the construction.

Airplanes that are constructed under these rules are certified as “experimental.” They have a few limitations on them like they can’t be used for charter or airline service, but they don’t often affect the uses made by private owners. Home-built planes like these cost significantly less than certified models, and they come in just as many shapes and sizes.

Related Posts